Jelly Form Fabrication

10/9/02 - 10/14/02

After five days of intense fabrication at Goddard and Riley in Oakland, CA, here are some snapshots of the fabrication process of the Jelly Form. The sculpture was shown at the New Fangle show in San Francisco from Oct 17 through November 16, 2002. For show information, go to www.genartsf.org.

Day Two: The foam core is roughed out with shur-forms. At MIT I made a scale model out of clay, mapped it to 1/4" sections, and drew the sections in Adobe Illustrator. I then made a scale model in foam core and printed the profiles full size on the plotter to use as a template to cut our the full size sections.

Day 4: The shape has been covered with fiberglass and red-tinted epoxy. We then hand covered the red with aluminum leaf. After this was complete, we coated the aluminum with epoxy that I had pigmented with oil paints.

Gary built a furnace in his driveway with foundation bricks, an enormous gas burner, and foil insulation. The roof was made of concrete board. In order to make it all work we had to plumb a gas line and build a customized venturi tube to fire the gas.

The 18 gallons of vinyl plastisol have melted after three days of contiunous cooking at 350 degrees. It was very difficult to regulate the oven temperature well.

The vinyl required regular stirring.

This is the light table, covered with polarizing film.

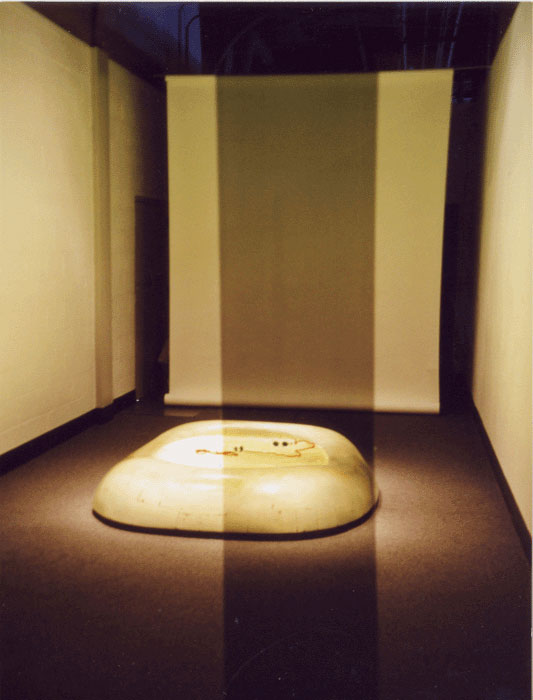

The Installed Sculpture.

The gel is about 2 inches thick and is birefringent when highly deformed.

Full body interaction causes localized audio responses.

The optical effect, viewed through a polarizing filter. The effect mimics the control mechanism used in LCD displays.

To view a short

quicktime movie, go here.

To view a conceptual overview of the piece, go here.